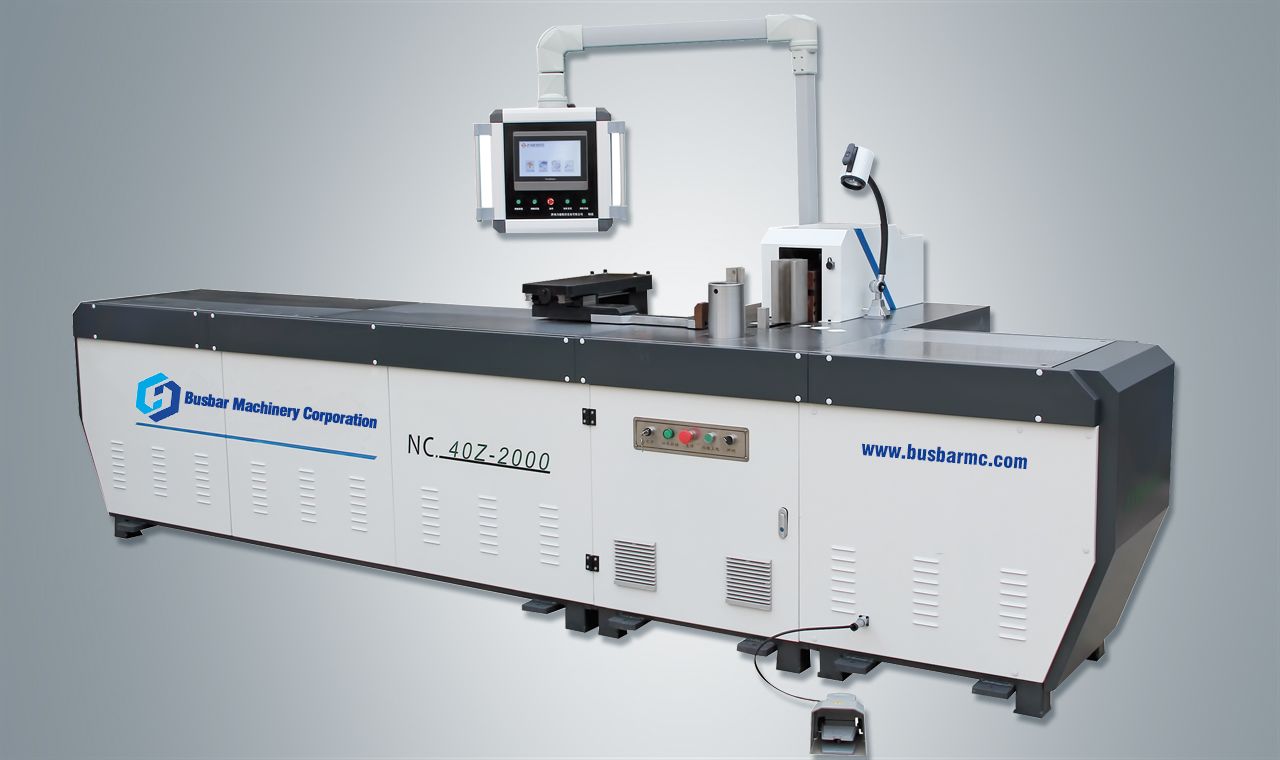

In the world of modern industrial automation,busbar bending machine innovation continues to shape the way we optimize manufacturing processes. One such innovation that has gained significant attention is the Busbar Bending Machine. This sophisticated piece of equipment is revolutionizing the way electrical power distribution systems are fabricated, offering unparalleled efficiency and precision.

The Busbar Bending Machine serves as a fundamental component in the production of busbars, which are essential in relaying electrical power within control panels, switchgear, and distribution systems. Traditional methods of bending busbars often relied on manual labor and were susceptible to inconsistencies, inaccuracies, and inefficiencies. However, the advent of the Busbar Bending Machine has changed the game.

One of the primary advantages of the Busbar Bending Machine is its ability to automate the bending process. This not only reduces reliance on human labor but also eliminates the potential for human errors. The machine’s computer-controlled precision ensures that each bend is executed with accuracy down to the millimeter, guaranteeing uniformity across the entire batch of busbars.

Flexibility is another noteworthy feature of these machines. With the ability to accommodate various busbar sizes and configurations, manufacturers can adapt to different project requirements without the need for extensive retooling or setup changes. This adaptability significantly cuts down on downtime and increases overall production efficiency.